Add to Cart

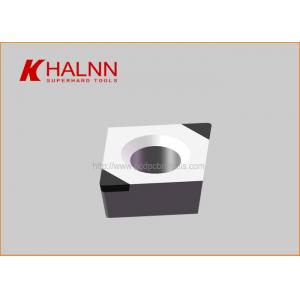

Finish Machining Hardened Steel Bearing better wear resistance with BH-H05 PCBN Cutting Tool

1. Halnn Tools Finish Machining Hardened Steel Bearing better wear resistance with BH-H05 PCBN Cutting Tool

As an important part of wind power generation, wind power bearings often use heat treatment technology to improve the performance requirements of wind power bearings. The heat-treated wind power bearing has high hardness, and the high-precision wind power bearing often uses grinding as the final processing step.

However, With the rapid development of the manufacturing industry, the competition in the market is intensifying. The adoption of high efficiency and low cost is the process of hard turning (turning grinding by turning) is the processing trend of the wind power bearing industry.

Advantages of hard turning (replacement grinding by turning) wind power bearings:

(1) High production efficiency;

(2) Hard turning is a clean production, which reduces the production cost, and the iron scraps turned off are more convenient for recycling;

(3) It is not necessary to use special machinery for hard turning of wind power bearings, and it can be carried out on existing ordinary lathes or CNC lathes;

(4) Most of the heat generated during the hard turning process is carried away by the chips to obtain a good surface quality.

2.Detailed Data of CBN Cutting Tool

| |||||||||

| Type | Dimension | Standard Chamfer | Grades | ||||||

| L(mm) | φI.C(mm) | S(mm) | φd(mm) | r(mm) | BN-H05 | BN-H10 | BN-H21 | ||

| CCGW060202-2S | 6.4 | 6.35 | 2.38 | 2.8 | 0.2 | S01015 S01020 S01025 S02020 S02025 | ● | ● | ● |

| CCGW060204-2S | 6.4 | 6.35 | 2.38 | 2.8 | 0.4 | ● | ● | ● | |

| CCGW060208-2S | 6.4 | 6.35 | 2.38 | 2.8 | 0.8 | ● | ● | ● | |

| CCGW09T302-2S | 9.7 | 9.525 | 3.97 | 4.4 | 0.2 | ● | ● | ● | |

| CCGW09T304-2S | 9.7 | 9.525 | 3.97 | 4.4 | 0.4 | ● | ● | ● | |

| CCGW09T308-2S | 9.7 | 9.525 | 3.97 | 4.4 | 0.8 | ● | ● | ● | |

| CCGW120404-2S | 12.9 | 12.7 | 4.76 | 5.5 | 0.4 | ◎ | ◎ | ◎ | |

| CCGW120408-2S | 12.9 | 12.7 | 4.76 | 5.5 | 0.8 | ◎ | ◎ | ◎ | |

| CCGW120412-2S | 12.9 | 12.7 | 4.76 | 5.5 | 1.2 | ◎ | ◎ | ◎ | |

3.Packing of Halnn Tools CBN Cutting Tool

4.Application Case of CBN Cutting Tool Machining Bearing

Finish Machining Hardened Steel Bearing better wear resistance with BH-H05 PCBN Cutting Tool

| Finish Machining Hardened Steel Bearing | |

| Machining Part:Finish Machining Hardened Steel Bearing |  |

| Workpiece Hardness:HRC 49 | |

| Finishing allowance: ≤ 1.2 mm | |

| Machining Materials:42CrMo4 | |

| Inserts Grade: BH-H05 CCGW060202-2S | |

| Cutting Parameters:ap=0.5mm,Fr=0.45mm/r,Vc=110m/min | |

| Machining effect: Compared with ceramic inserts, the cutting speed is higher than that of ceramic tools by 22% | |

5.FAQ

1. Are you a trading company or manufacturer ?

A: We are a manufacturer and wholesaler for diamond & CBN (cubic boron nitride) abrasives and tools.

2. How long is your delivery time?

A: Generally it is 3 -7 days.

2. Do you provide samples ? Is it free or extra ?

A: Normally we do not offer free samples, we could offer the sample for testing, but shipping fee is to be paid by customer as a company policy!